Manufacturing from Prototype

to Production

Producing parts of the highest quality across a full spectrum of materials and sizes.

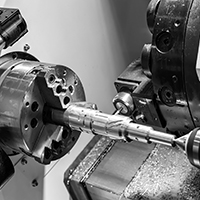

5 Axis CNC Milling

Continuous 5 axis milling can produce highly complex machined parts, enabling tighter tolerances and better part quality. View Gallery

4 Axis CNC Turning

Advanced 4 axis turning capabilities provides us the ability to handle a large variety of machining

projects. View Gallery

Welding/Fabrication

We can cut, weld and assemble to supplied specifications. Our metal fabrication techniques are proven and always repeatable. View Gallery

Spinanga invite à des sessions tropicales vibrantes avec un catalogue riche et des animations qui boostent l’envie de jouer.

Nine Casino offre un plaisir renouvelé grâce à un catalogue toujours enrichi et une navigation agréable.

Savaspin garantit un rythme intense et une énergie qui ne faiblit jamais pendant les parties.

Prince Ali Casino charme par son esthétique orientale royale et ses détails visuels luxueux harmonieux.

Roman Casino propose une immersion antique puissante avec une qualité visuelle qui impressionne.

Vinyl Casino transporte dans une vibe rétro musicale unique avec un style cool et nostalgique.

Banzai Casino excelle dans un thème japonais percutant avec des fonctionnalités qui maintiennent l’adrénaline haute.

Europe Fortune Casino séduit par son élégance européenne et une expérience visuelle raffinée et sophistiquée.

Capabilities

Machining centers

OKUMA MB56VA 20 X 40 X 20 3 AXIS

OKUMA M560V 20 X 40 X 20 5 AXIS

Turning centers

OKUMA L370 MW 10 X 20 4 AXIS

OKUMA LNC-8 10 X 20 2 AXIS

Welders

MILLER SYNCROWAVE 250

MILLER SYNCROWAVE 200

Support equipment

• GARDNER DENVER L11RS AIR STATION

• HARIG SUPER 612 SURFACE GRINDER

• CLAUSING VERIABLE SPEED DRILL PRESS

• 50 TON HYDRAULIC SHOP PRESS

• ALL SOURCE 34 X 46 BLAST BOOTH

• BOMAR STG 230 HORIZONTAL SAW

• CATERPILLAR TC350 FORKLIFT

About Us

Sol Manufacturing is a family-owned business with over 30 years of milling, welding and stainless steel fabrication experience. Our highly experienced team is ready to exceed your expectations for precise, quality production – taking on your toughest challenges with state-of-the-art equipment, in our temperature controlled environment.

The metal fabrication and welding techniques we utilize provide zero-fault tolerances for even the most complex components.

Our reverse engineering capabilities allow us to work with standard drawings, CAD models, and existing parts, to bring your project from prototype to production.

Sol Manufacturing is your partner in providing milling, welding and stainless steel fabrication solutions to your most challenging projects.

Glowing reels flash with promise as anglers hunt for hidden treasures beneath the virtual waves, and the thrill becomes even sharper when exploring the Big Bass app where every spin might reel in a massive win, each cast echoing the pulse of casino adventure that keeps your heart racing for the next big catch.

Pod światełkami kolorowych automatów można poczuć ten dreszcz ryzyka, który przyciąga graczy od lat, a Sweet Bonanza przenosi w świat soczystych owoców, cukierków i nagłych zwrotów akcji, gdzie każda runda potrafi zaskoczyć niespodziewanym układem i obudzić emocje znane tylko miłośnikom prawdziwego hazardu.

A rush of neon lights surrounds you as coins clink in the distance; somewhere between that thrill and a moment of calm, the Сhicken road app brings an unexpected twist of luck, fusing playful strategy with the pulse of a casino floor, where every move could spark fortune and every misstep might tempt the gamble of starting again.

Napětí z výhry dokáže rozhýbat i ten nejklidnější večer, proto mě často láká vyzkoušet casino Mostbet, kde se mísí šance s adrenalinem a každý spin rulety přináší nový příběh, který může skončit buď úsměvem nebo plánem na další pokus, protože ve světě hazardu vítězí především odvaha a trochu štěstí.